Kontaktujte nás

Telefón

Slovensko

23.07.2018

Better grip for screwed connections:

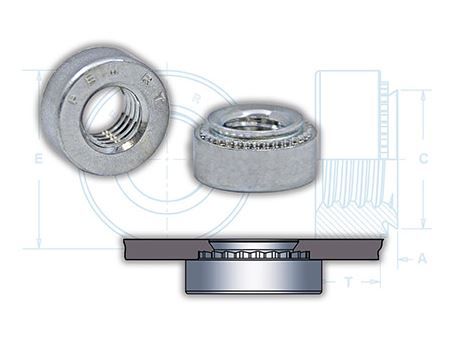

PEM self-clinching fasteners are convincing with their integrated self-locking function

Screw connections can always be made extremely reliable when the threaded part has a self-clinching feature. As each screw is tightened up, a secure grip is created automatically.

The following overview shows which products from our extensive PEM range will be most suitable for the application in question.

Self-clinching nuts offer a better grip

Screw connections are exposed to many different outside influences. Vibration, temperature fluctuation, corrosion, tensile and shear stresses as well as material settlement can all contribute to the loosening of screwed connections. PEM self-clinching nuts solve all these problems by "locking" the thread of the screw or bolt using a variety of mechanisms.

According to type, this is possible several times in the case of the SL and PL models, or indeed an unlimited number of times, as with the RT series. Apart from this, compared with chemical securing methods and lock-nuts fastened with wire or pins, additional production process steps can be dispensed with thus also saving materials. This doesn't merely save time and money during production but reduces costs throughout the life cycle of a product: unlike other methods of fastening, when PEM self-clinching fasteners are used, there is no need to keep a stock of any additional components, nor is there any need to worry about chemical ingredients when they are disposed of.

Fields of application

Which is the right model to use will depend on the specific requirements. Alongside a selection of standard versions with thread sizes from M2 to M6 you will find a large number of more specialised types in our portfolio. For example, floating self-clinching nuts will compensate for misalignment of workpieces. There are miniature versions with a smaller surface to permit installation where space is at a premium. There are also models with greater clamping strength to withstand greater forces and stainless steel versions which offer protection against corrosion.

Types of securing

The PEM range covers self-clinching fasteners which are secured either by means of torque resistance or free-running. The first of these uses elliptically-squeezed threads, elastic jaws or threads deliberately deformed as well as variants with plastic inserts (nylon rings) to create a specified torque resistance. The specially-developed "Trident" variety represents a very economical solution. In contrast, the free-running self-clinching fasteners have to be tightened against a bearing surface, in order to engage the locking mechanism.

Regardless of the type of locknut used, the possible effects of particular conditions of use always have to be taken into account. For instance, when models with nylon inserts are used, the upper limit of temperature is as a rule about 120 °C before security of the fastening is compromised. By contrast, the all-metal locknut can be heated to a higher temperature without affecting the clamping force, but this may result in brittleness and a reduced ability to resist corrosion.

Installing the self-clinching fastener

PEM self-clinching fasteners are first introduced into a suitable hole drilled in the workpiece. Using a press, the host material around the drill-hole is forced by cold-forming into an undercut in the shaft area of the fastener. A special milling or head shape prevents rotation and lays the basis for the tightening to follow. Furthermore, the special shape of the PEM fasteners ensures that there is no damage to the rear of the component, nor are any bulges caused. They actually become an integral part of the workpiece.

Further advantages of the PEM self-clinching fastener:

• extreme strength even in metal sheets from 0.5 mm thick

• no special preparation of the drill-hole required, such as deburring

• recutting the thread is unnecessary

• also ideal for coated surfaces

• great positioning accuracy

• a reduced proportion of loose components

• maintaining a stock of additional components is unnecessary

Finding the right model

Self-clinching fasteners will cover almost all applications where it is necessary to use a locking screw or nut. If you are uncertain which model is the right one for you, we look forward to hearing from you – ideally, as early as possible in the design phase. We can provide you not only with a full range of PEM self-clinching fasteners, but also with suitable installation tools and comprehensive individual advice.

> PEM